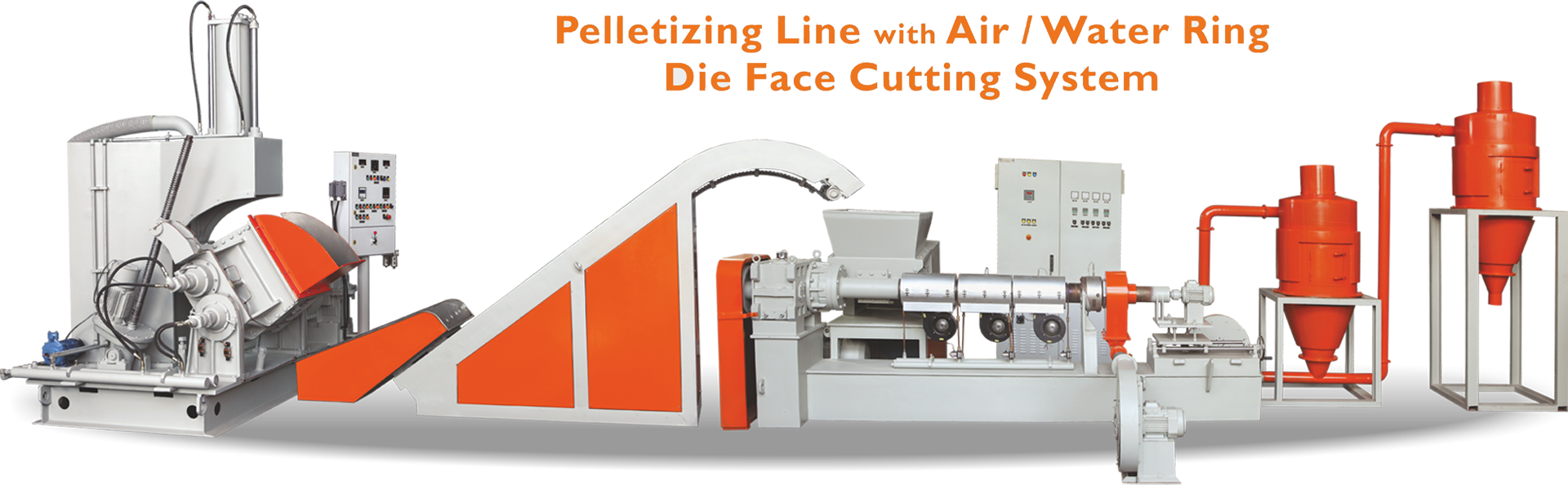

Pelletizing Lines with Air & Water Ring Die Face Cutter

- Kneader Piston is Hydraulically or Pneumatically operated

- Various electrical & Mechanical safety interlocks

- Heavy Duty Gear Box

- Tilting angle upto 145 degree

- Excellent Quad blade Rotor design

- Cooling provision in Rotors, Chamber, and pressure lid

- Dual Electric Control Panel option is available to keep the major components safe from

dust and heat.

- PLC Control in automatic/manual mode is optionally available

- AC variable drive for main motor is optional and suggested for the energy saving and

longer life of the prime movers in the machine

- Lubrication system installed for all moving parts to give smooth operation

- Best quality and innovated sealing system gives more than 95% saving in leakage from

the Rotors and dust coming out in the ambient

- Multiple feeding option can be offer as per customer convenience – Front feeding, Back

feeding, and Top feeding.

- Our unique Screw design is suitable for the maximum application – so one machine can

process various polymers in different formulation

- Our Screw & Barrel is manufactured with the highest quality of Nitride Steel, duly nitride

and polished, having hardness of 60-65 HRC

- Our barrels are Heated by reputed make Heaters, and cooled by dual cooling process ,

one is reputed make Blowers , and other is water cooling operated by cooled water

and solonoide valves, to give precise temperature control while processing

- Heavy Duty Gear Box from reputed manufacturer of the country

- Force Feeder rotors are specially designed for different application for smooth and even

feeding of the material to be processed. It is driven by heavy duty gear box and

AC Variable motor for controlled feeding

- Air Ring /Water Ring/Strand cutting options available on similar platform, and can be

changed without much efforts

- Die Head & Die plate are made up with special alloy for longer life

- Electric control cabinet to operate the machine is equipped with Highest Quality , perfect

selection of the switch gears, Timers and Temperature sensor and controller to give

smooth operation for longer years.

- Dual Panel option is available to keep the major components safe from dust and heat.

- PLC Control option in automatic/manual mode is optionally available

- AC Variable Drives and Temperature Controller are from reputed brands of the industry

and can be choose mutually also.

- Cutting/Cooling Chamber and all other parts & components are of stainless steel 304,

wherever there is a contact of water & processed material

- Centrifugal dryer is dynamically balances and equipped with Torque coupling

- Centrifugal dryer is specially designed for longer bearing life, and it is equipped with

immediate moisture removal silo, which allows to remove moisture from the material

- All connected pipes are SS304, connected with 360 degree rotational clamps, which makes

more comfortable to clean during product change, and customer can place the silo

as per the convenience to save the space

- Viberatory Classifier gives you the perfect classified final pellet and removes all unwanted

fines